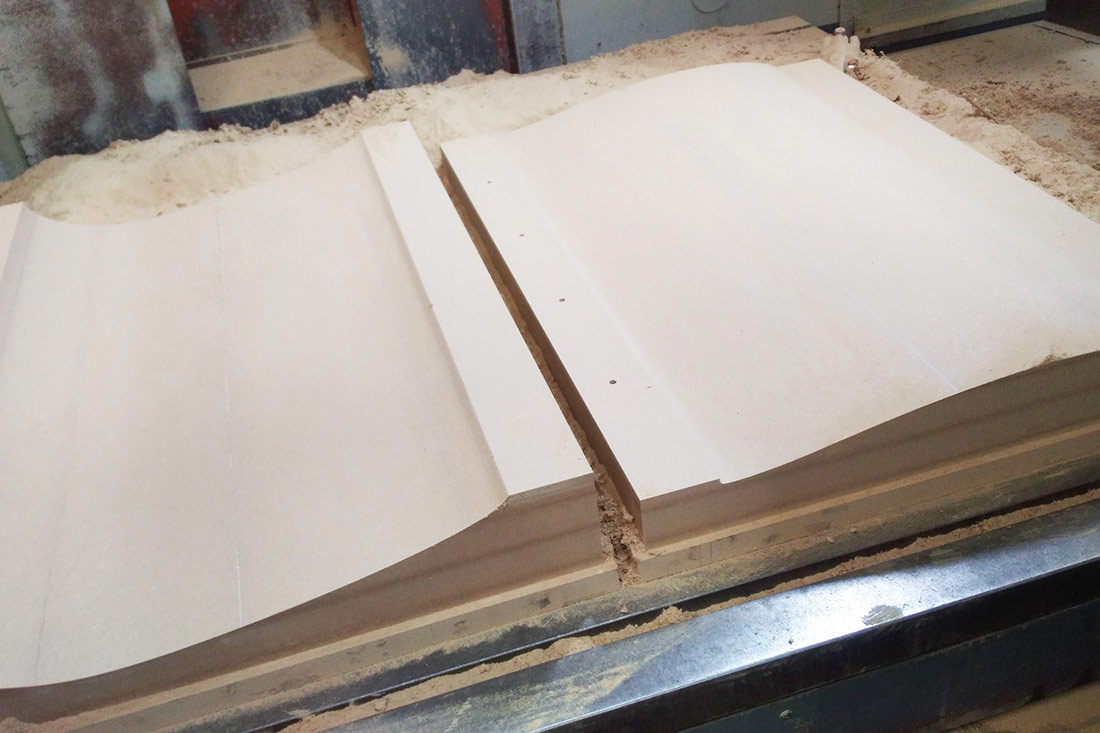

Tecdigital Maquiações 3D supports the FST Lisboa for some years with the manufacture of MDF molds for the construction of team cars. The company's participation in the project has been proved important with the evolution of prototypes, which each year requires more innovative designs and, consequently, more complex molds.

It is important to Tecdigital to be involved with innovative student projects, encouraging them to develop their projects and gain experience. This tunrs possible the better qualification for new generations of technicians while allowing the development of national technologies. Being part of this process is a great pride for a company that is committed to contributing.

The long-standing relationship with the team also provides good times, especially in the manufacturing period, where there is fraternization and exchange of experience between team and company members.

FST Lisboa is a Formula Student team from Instituto Superior Técnico. It is an extracurricular project in which students must develop an electrical formula.

Partnership with Instituto Superior Técnico de Lisboa

- About Tecdigital Maquiações 3D supports the FST Lisboa for some years with the manufacture of MDF molds for the construction of team cars.

×

Innovative Projects

I.S.E.P. INNOVATIVE PROJECTS

Innovative Project, TECDIGITAL and I.S.E.P. partnership

Innovative Project, TECDIGITAL and I.S.E.P. partnership

- About DcS Double curvature surface in reinforced concrete, practical case study.

- Name Luís Pedro Esteves (engineer, ISEP)

- Name Gonçalo Castro Henriques (architect, X-REF)

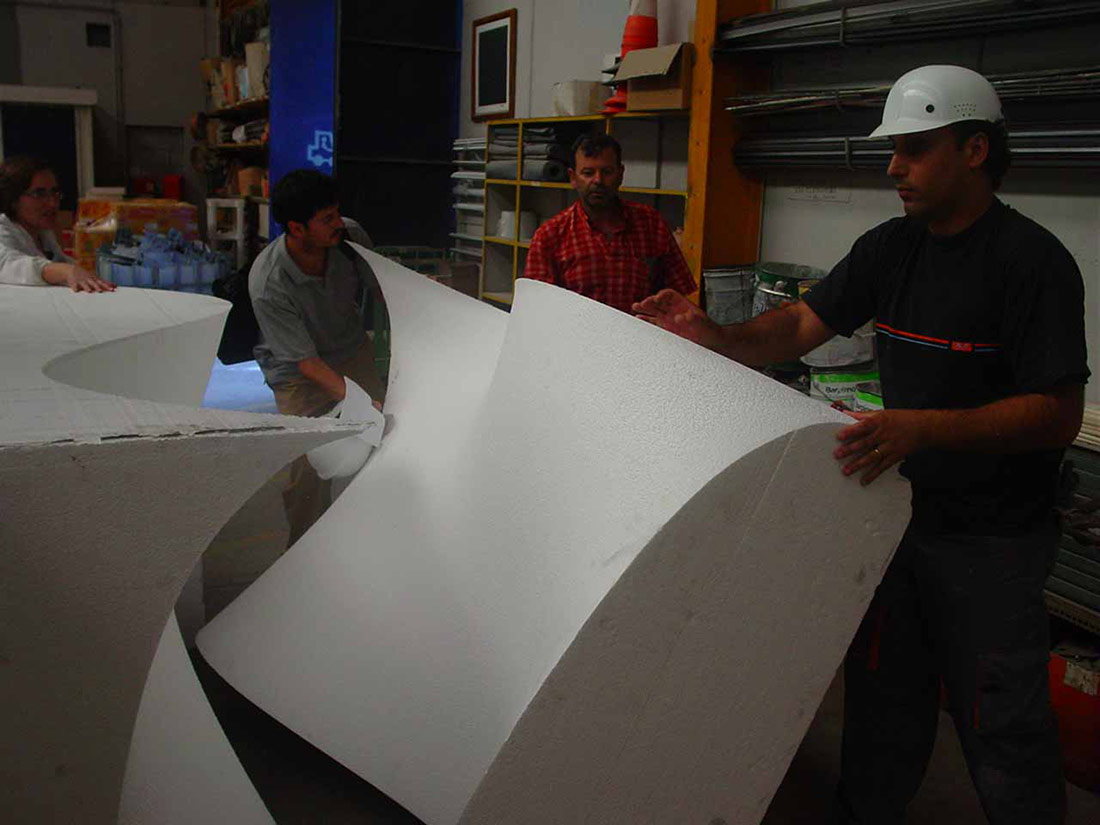

This project results from the collaboration between Instituto Superior de Engenharia do Porto (ISEP) and the architecture studio XREF| referências cruzadas. The options of modelling and visualization of complex forms in projects have been increasing. However, the use of digital tools is commonly associated to representation, using the computer as a tool to anticipate the final shape. At the early stages of the project and during its execution, there are not many preoccupations in relation to the materials and constructive techniques. Using the different stages of the project as a whole, involving simultaneously the different disciplines may result in a better quality at an admissible cost. On the other hand, the most recent investigation in what concerns new materials and constructive procedures, opens a creative window for experimentation, applied to complex shapes which intimately approach to nature.

This investigation project tried to make into a whole the different stages of development between the conception and the digital production, of the multiple involved fields coordinated by Luís Pedro Esteves(engineer, ISEP) and Gonçalo Castro Henriques (architect, X-REF).

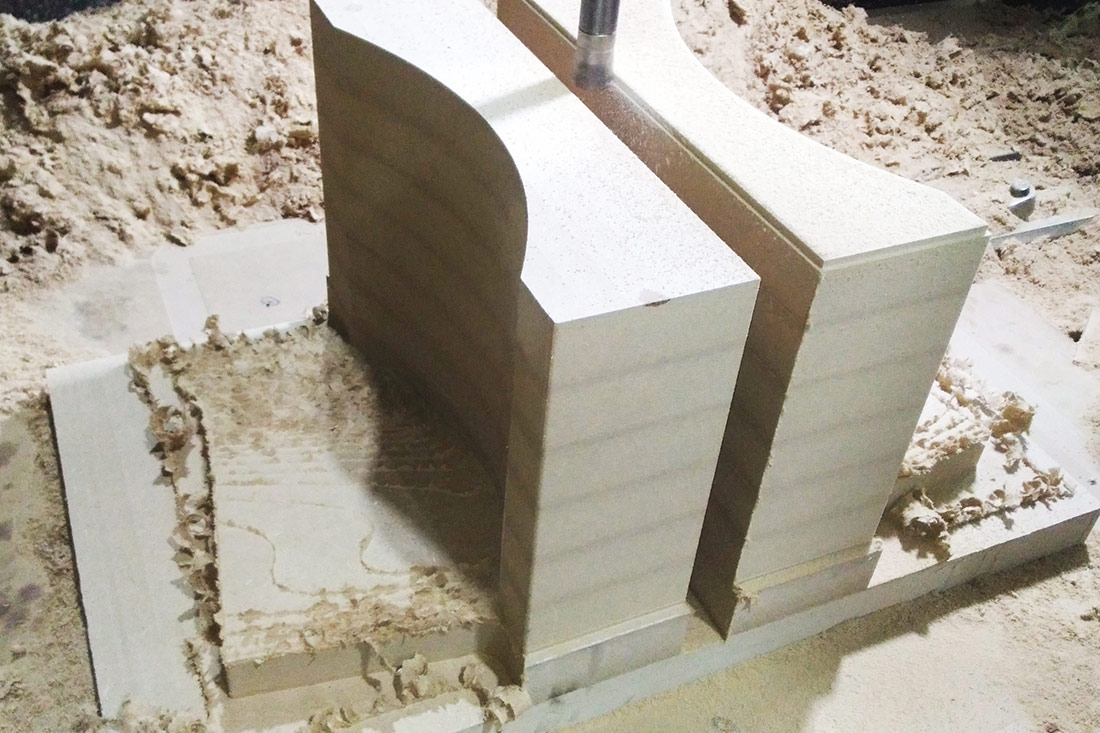

The surface created in 7cm concrete, with 2.00x1.20x0.60 and 750 Kg was developed using EPS moulds, which were trimmed by numeric information transmitted to a CNC machine. After, these moulds were used as formwork for the reinforced concrete piece. This alternative process of concrete formwork allows a large spectre of architectonic possibilities concerning the shape and texture, integrated in structural elements.

This project involved many companies, but the contribution of TECDIGITAL was determinant not only due to its competence and technical know-how in the processing and use of the CNC machines, but also to an innovative position, in view of a technology not much explored in building construction.

Gonçalo Castro Henriques (architect, X-REF)

This investigation project tried to make into a whole the different stages of development between the conception and the digital production, of the multiple involved fields coordinated by Luís Pedro Esteves(engineer, ISEP) and Gonçalo Castro Henriques (architect, X-REF).

The surface created in 7cm concrete, with 2.00x1.20x0.60 and 750 Kg was developed using EPS moulds, which were trimmed by numeric information transmitted to a CNC machine. After, these moulds were used as formwork for the reinforced concrete piece. This alternative process of concrete formwork allows a large spectre of architectonic possibilities concerning the shape and texture, integrated in structural elements.

This project involved many companies, but the contribution of TECDIGITAL was determinant not only due to its competence and technical know-how in the processing and use of the CNC machines, but also to an innovative position, in view of a technology not much explored in building construction.

Gonçalo Castro Henriques (architect, X-REF)